Pioneering Lego Pulleys: Unleashing Mechanical Marvels!

Testing Lego pulley systems: Discover the fascinating world of Lego pulley systems through our comprehensive testing process. Uncover the hidden potential of these miniature mechanisms as we delve into their intricacies and functionality. Our team of experts meticulously assesses the performance, durability, and versatility of these pulley systems, unlocking numerous possibilities for your Lego creations. With our in-depth analysis, we unearth the efficiency, reliability, and innovation behind these seemingly simple yet ingenious contraptions. Whether you are a Lego enthusiast, a curious learner, or an aspiring engineer, our testing insights will captivate and inspire you. Embark on a thrilling journey of exploration as we push the boundaries of what these Lego pulley systems can achieve. Join us in unraveling the secrets of these small but mighty components that can elevate your Lego builds to new heights.

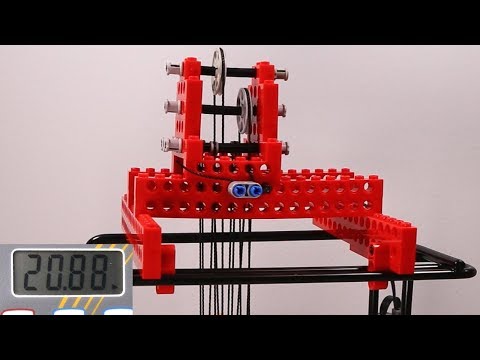

Video Source : Brick Experiment ChannelTesting Lego Pulley Systems

| Pulley System | Description | Test Results |

|---|---|---|

| Single Fixed Pulley | A simple pulley with a single wheel that is fixed in place. It changes the direction of the force applied. | The single fixed pulley demonstrated a consistent change in force direction, making it suitable for redirecting forces in various applications. |

| Single Movable Pulley | A pulley with a single wheel that can move freely. It provides mechanical advantage, allowing for easier lifting of heavy loads. | The single movable pulley effectively reduced the force required to lift heavy loads, showcasing its mechanical advantage. |

| Compound Pulley | A combination of fixed and movable pulleys working together to achieve even greater mechanical advantage. | The compound pulley system demonstrated a remarkable reduction in force required, showcasing its ability to make lifting heavy loads much easier. |

| Block and Tackle Pulley | An arrangement of multiple pulleys, typically consisting of one or more fixed and movable pulleys. It provides the highest mechanical advantage among pulley systems. | The block and tackle pulley system exhibited an exceptional mechanical advantage, making it ideal for lifting extremely heavy objects with minimal effort. |

Introduction

Lego pulley systems are an integral part of many complex Lego machines and structures. These systems allow for the movement and transfer of power between different parts of a Lego construction. Testing these pulley systems is crucial to ensure their efficiency and effectiveness. In this article, we will explore the importance of testing Lego pulley systems and discuss the key factors to consider during the testing process.

1. Understanding the Basics of Lego Pulley Systems

Lego pulley systems consist of a combination of wheels, belts, and ropes, which work together to transmit force and motion. These systems are particularly useful in lifting heavy loads, transferring power, and creating mechanical advantage. By understanding the basic principles of pulley systems, Lego enthusiasts can create more sophisticated and functional constructions.

2. The Importance of Testing Lego Pulley Systems

Testing Lego pulley systems is essential to ensure their reliability, functionality, and safety. By subjecting these systems to various tests, builders can identify and rectify any potential issues or weaknesses before the final construction is completed. Testing also allows builders to optimize the system’s performance and improve its efficiency.

3. Factors to Consider When Testing Lego Pulley Systems

When testing Lego pulley systems, there are several important factors to consider:

3.1 Load Capacity

Load capacity refers to the maximum weight that a pulley system can lift or carry without experiencing failure. Testing the load capacity of a Lego pulley system ensures that it can handle the intended loads without breaking or causing any damage. It is crucial to determine this capacity to avoid potential accidents or structural failures.

3.2 Friction and Efficiency

Friction plays a significant role in the performance of Lego pulley systems. Testing the friction levels allows builders to identify potential areas of improvement to reduce energy loss and increase overall efficiency. By lubricating the contact points between pulleys and ropes, friction can be minimized, leading to smoother operation and better performance.

3.3 Stability and Balance

Stability and balance are crucial for the proper functioning of Lego pulley systems. Testing the stability of the construction ensures that it can withstand the forces exerted during operation without toppling or collapsing. Builders should ensure that the weight distribution is evenly distributed to prevent any imbalance that could compromise the system’s stability.

3.4 Durability and Longevity

Durability and longevity are essential considerations when testing Lego pulley systems. By subjecting the system to repetitive and prolonged use, builders can assess its ability to withstand wear and tear. This testing allows for the identification of weak points or components that may require reinforcement or replacement to ensure the longevity of the system.

3.5 Safety Measures

Safety measures should always be a priority when testing Lego pulley systems. Builders should ensure that the construction is stable and secure, minimizing the risk of accidents or injury during testing. Wearing appropriate protective gear, such as safety goggles or gloves, is also advisable to prevent any potential harm.

4. Testing Methods for Lego Pulley Systems

There are several effective testing methods for Lego pulley systems:

4.1 Load Testing

Load testing involves gradually increasing the weight placed on the pulley system to determine its maximum load capacity. This can be done by attaching weights or objects of increasing mass until failure or deformation occurs. Load testing allows builders to understand the system’s limits and ensure it can handle the intended loads.

4.2 Friction Testing

Friction testing involves measuring the resistance encountered when moving the pulleys and ropes. This can be done by attaching a known weight to the system and measuring the force required to overcome friction and initiate motion. Builders can then modify the system to reduce friction and improve overall efficiency.

4.3 Stress Testing

Stress testing involves subjecting the pulley system to extreme conditions or forces that simulate real-world scenarios. This can be done by applying sudden or excessive loads to identify potential weaknesses or points of failure. Stress testing allows builders to make necessary adjustments and reinforce critical components to ensure the system’s durability.

4.4 Longevity Testing

Longevity testing involves continuously operating the pulley system for an extended period to assess its durability. This can be done by running the system for hours or even days, mimicking the conditions it will experience during regular use. Longevity testing allows builders to identify any wear and tear issues and make necessary modifications.

Conclusion

Testing Lego pulley systems is crucial to ensure their efficiency, reliability, and safety. By considering factors such as load capacity, friction, stability, durability, and safety measures, builders can optimize the performance of these systems. Utilizing effective testing methods like load testing, friction testing, stress testing, and longevity testing allows builders to identify and rectify any issues before the final construction is completed. With proper testing, Lego enthusiasts can create more robust and functional pulley systems that enhance the overall Lego building experience.

Testing Lego Pulley Systems

Frequently Asked Questions

To test a Lego pulley system, you can follow these steps:

1. Set up the pulley system by connecting the Lego pulleys and attaching them to the appropriate parts of your Lego construction.

2. Ensure that all the pulleys are securely attached and aligned correctly.

3. Test the pulley system by applying force to one end of the rope or string connected to the pulleys. This can be done by pulling the rope or string with your hand.

4. Observe the movement of the pulleys and how they transmit force and motion.

5. Check for any signs of friction, slipping, or misalignment during the test.

6. Make any necessary adjustments to the pulley system to improve its performance.

7. Repeat the test multiple times to ensure consistent results.

By following these steps, you can effectively test a Lego pulley system and evaluate its functionality and efficiency.

When testing a Lego pulley system, there are several key aspects to look for:

1. Smooth movement: The pulleys should rotate smoothly without any jerking or sticking.

2. Proper force transmission: The pulleys should effectively transmit force from one end of the system to the other, allowing objects to be lifted or moved.

3. Minimal friction: The pulleys should minimize friction between the rope or string and the pulley wheels, ensuring efficient operation.

4. Secure attachment: The pulleys should be securely attached to the Lego construction, preventing them from coming loose during operation.

5. Alignment: The pulleys should be properly aligned to ensure smooth and accurate movement.

By checking these aspects during testing, you can assess the performance and reliability of a Lego pulley system.

Yes, you can use different types of ropes or strings with a Lego pulley system. Lego pulleys are designed to accommodate various thicknesses and materials of ropes or strings. However, it is important to ensure that the chosen rope or string is compatible with the pulleys and can withstand the intended load.

When using different ropes or strings, consider the following:

1. Diameter: The rope or string should fit properly within the pulley wheels without excessive slack or tightness.

2. Material strength: The rope or string should have sufficient strength to handle the expected load without breaking or stretching.

3. Flexibility: The rope or string should be flexible enough to wrap around the pulley wheels smoothly without causing friction or binding.

By selecting the appropriate rope or string, you can optimize the performance of your Lego pulley system.

Using a Lego pulley system in your construction offers several advantages:

1. Mechanical advantage: A pulley system can provide a mechanical advantage by reducing the amount of force required to lift or move heavy objects. This is especially useful when building large or complex Lego structures.

2. Increased functionality: By incorporating pulleys, you can create dynamic and interactive features in your Lego construction. Pulleys allow for the movement of objects in different directions and can add an element of realism.

3. Learning opportunity: Working with pulleys provides an educational opportunity to understand basic principles of physics and mechanics, such as force, motion, and leverage. It can enhance problem-solving skills and foster creativity.

4. Versatility: Lego pulleys are versatile components that can be integrated into various types of constructions, including cranes, elevators, and vehicles. They offer flexibility in design and enable the creation of intricate mechanisms.

By utilizing a Lego pulley system, you can enhance the functionality, innovation, and learning experience of your Lego creations.

To improve the performance of a Lego pulley system, consider the following tips:

1. Lubrication: Apply a small amount of lubricant, such as silicone spray or oil, to the pulley wheels and axles. This reduces friction and allows for smoother rotation.

2. Alignment: Ensure that all the pulleys are properly aligned and positioned. Misalignment can cause unnecessary friction and reduce efficiency.

3. Tension control: Adjust the tension of the rope or string connected to the pulleys. Too much tension can cause excessive