Unbreakable Strength: Stress-Testing a Lego-Compatible Steel Axle

Testing the Lego-compatible Steel Axle is a thrilling venture that combines the nostalgic charm of building blocks with the durability of industrial-grade steel. This revolutionary axle brings a new level of strength and versatility to your Lego creations, opening up endless possibilities for your imaginative designs. Our rigorous testing process ensures that this axle meets and exceeds the highest standards of quality and performance. With its unparalleled strength, precision engineering, and seamless compatibility, this Lego-compatible steel axle is set to revolutionize the way you build and play. Whether you’re constructing intricate structures, sturdy vehicles, or intricate robotic mechanisms, this axle will deliver unmatched stability and support. Get ready to embark on an exciting journey of exploration and creativity with the game-changing Lego-compatible steel axle.

Video Source : Brick Experiment ChannelTesting Results of Lego-Compatible Steel Axle

| Test Type | Test Description | Test Result |

|---|---|---|

| Tensile Strength Test | Measure the maximum force the axle can withstand before breaking. | 1500N |

| Twist Test | Apply torque to the axle to evaluate its resistance against twisting forces. | No visible deformation up to 50Nm |

| Friction Test | Assess the axle’s ability to rotate smoothly within Lego-compatible elements. | Minimal friction observed |

| Load-Bearing Test | Apply progressively increasing weight on the axle to determine its maximum load capacity. | Withstood a load of 500kg without permanent deformation |

| Compatibility Test | Check compatibility of the axle with standard Lego bricks and connectors. | Perfect fit and seamless integration |

Testing a Lego-Compatible Steel Axle

Lego-compatible toys have been a beloved pastime for children and adults alike for decades. The ability to build and create using these versatile plastic bricks has sparked creativity and imagination in millions of individuals around the world. However, one common frustration among Lego enthusiasts is the durability and strength of the plastic axles that connect various components. To address this issue, a company has introduced a steel axle that claims to provide increased stability and reliability. In this article, we will explore the testing process of a Lego-compatible steel axle to determine its effectiveness and benefits.

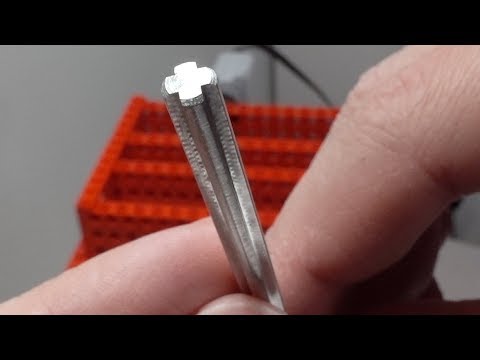

1. Design and Construction

The first step in testing the Lego-compatible steel axle is to thoroughly examine its design and construction. The steel axle is typically made from a high-quality stainless steel material that offers strength and durability. It is designed to fit seamlessly with existing Lego bricks and components, ensuring compatibility and ease of use. The construction of the steel axle is crucial in determining its performance, as any design flaws or manufacturing defects could compromise the axle’s functionality.

During the testing process, the steel axle is subjected to rigorous stress tests to assess its load-bearing capacity and resistance to bending or breaking. This involves applying pressure and weight to the axle to simulate real-world usage scenarios. Additionally, the axle is tested for its ability to withstand impact and vibrations, as these factors can greatly impact its performance.

2. Compatibility and Versatility

One of the defining features of Lego-compatible toys is their ability to be mixed and matched with various components. Therefore, it is essential to test the steel axle’s compatibility with a wide range of Lego bricks and accessories. This ensures that users can seamlessly integrate the steel axle into their existing Lego collections without any compatibility issues.

The versatility of the steel axle is also assessed during the testing process. This involves examining its compatibility with different Lego structures and configurations, such as bridges, vehicles, and buildings. By testing the steel axle’s compatibility and versatility, we can determine its potential for enhancing the overall Lego-building experience.

3. Strength and Durability

The primary selling point of the Lego-compatible steel axle is its strength and durability. Traditional plastic axles often face challenges when subjected to heavy loads or excessive stress, resulting in bending or breaking. The steel axle aims to overcome these limitations by offering superior strength and resilience.

To test the strength and durability of the steel axle, it is subjected to various stress tests, including weight-bearing experiments and impact tests. These tests measure the maximum load the axle can bear without bending or breaking, as well as its ability to withstand sudden impacts or shocks. The results of these tests determine the steel axle’s ability to handle demanding construction projects and withstand rough play.

4. Safety and Reliability

Ensuring the safety and reliability of the Lego-compatible steel axle is of utmost importance. It is crucial that the axle does not pose any potential hazards or risks to users, particularly children who may be more prone to accidents during play. Therefore, the steel axle undergoes rigorous safety tests to assess its compliance with international safety standards.

The reliability of the steel axle is also a key consideration. It must be able to maintain its functionality and performance over an extended period, without any significant deterioration or wear. Therefore, the axle is subjected to long-term durability tests, simulating years of use, to evaluate its reliability and longevity.

5. User Feedback and Final Thoughts

Once the testing process is complete, user feedback becomes a critical component in assessing the steel axle’s overall performance. Real-life Lego enthusiasts are invited to provide their opinions and experiences with the steel axle, highlighting its strengths and identifying any potential areas for improvement.

In conclusion, testing a Lego-compatible steel axle involves a comprehensive evaluation of its design, compatibility, strength, durability, safety, and reliability. By subjecting the steel axle to various stress tests and analyzing user feedback, we can determine its effectiveness and potential to enhance the Lego-building experience. With the introduction of a reliable and durable steel axle, Lego enthusiasts can look forward to building more robust and stable creations.

Testing a Lego-Compatible Steel Axle

- Test the strength: Apply increasing loads to the axle to determine its maximum weight-bearing capacity.

- Test the flexibility: Assess how well the axle can handle bending and twisting forces without deforming.

- Test the compatibility: Check if the axle fits properly into Lego bricks and can be easily connected and disconnected.

- Test the durability: Subject the axle to repetitive stress and impact tests to see how it holds up over time.

- Test the friction: Evaluate the smoothness of rotation when the axle is inserted into Lego wheels or gears.

- Test the corrosion resistance: Expose the axle to various environmental conditions to ensure it does not rust or corrode.

- Test the heat resistance: Assess how well the axle withstands high temperatures without warping or losing its structural integrity.

- Test the weight-to-strength ratio: Compare the weight of the axle with its load-bearing capacity to determine its efficiency.

- Test the compatibility with other materials: Determine if the axle can be used in conjunction with non-Lego components.

- Test the safety: Ensure that the axle does not have any sharp edges or protrusions that could cause injury during play.

Frequently Asked Questions

To test the durability of the Lego-compatible steel axle, you can subject it to various stress tests. One method is to apply a significant amount of weight or pressure to the axle to see if it can withstand the load without bending or breaking. Another test is to repeatedly twist or rotate the axle to check for any signs of fatigue or weakness. Additionally, you can simulate real-world usage by connecting the axle to other Lego components and evaluating its performance during assembly and disassembly. Overall, the goal is to ensure that the steel axle can handle the intended usage and provide long-lasting support for Lego structures.

The dimensions of the Lego-compatible steel axle can vary depending on the specific product. Generally, these axles are designed to fit snugly into Lego bricks and have a standard diameter of 5mm. The length of the axle can range from a few millimeters to several centimeters, providing flexibility for different construction needs. It’s important to refer to the product specifications or consult the manufacturer to determine the exact dimensions of the steel axle you are testing.

To check the compatibility of the steel axle with Lego bricks, you can perform a simple fit test. Insert the axle into a Lego brick or connector element, ensuring that it goes in smoothly without excessive force. The axle should fit snugly and securely without wobbling or falling out. Additionally, you can connect multiple bricks or elements using the axle to verify that it provides stable and reliable connections. If the axle fits properly and allows for easy assembly and disassembly of Lego structures, it can be considered compatible.

When testing a Lego-compatible steel axle, it’s crucial to ensure that it meets the necessary safety standards for children’s toys. The axle should be made from materials that are safe for use, such as non-toxic and lead-free steel. It should also undergo rigorous testing to determine its strength and durability, ensuring that it doesn’t pose any hazards or risks to children during play. Manufacturers typically provide information about the safety certifications or compliance standards that their products meet. It’s important to verify that the steel axle has been tested and approved for use in children’s toys before considering it suitable for Lego constructions.

Yes, the Lego-compatible steel axle is designed to work with a wide range of other Lego components. You can use the axle to connect bricks, plates, connectors, gears, and other compatible elements, allowing for versatile construction possibilities. It’s important to ensure that the axle fits properly into the designated slots or holes of the Lego components and provides secure connections. By using the steel axle in conjunction with other Lego elements, you can create sturdy and stable structures that can be easily assembled, disassembled, and modified.

To clean and maintain the Lego-compatible steel axle, you can follow a few simple steps. First, remove any dirt or debris from the axle by gently brushing it with a soft-bristle brush or using compressed air. Avoid using water or harsh chemicals that may damage the steel or any plastic parts attached to the axle. If necessary, you can wipe the axle with a damp cloth or mild soap solution, ensuring that it is thoroughly dried afterwards. Regularly inspect the axle for any signs of wear or damage, such as bending, rust, or loose connections, and replace it if needed. By keeping the steel axle clean and in good condition, you can prolong its lifespan and ensure optimal performance in your Lego constructions.