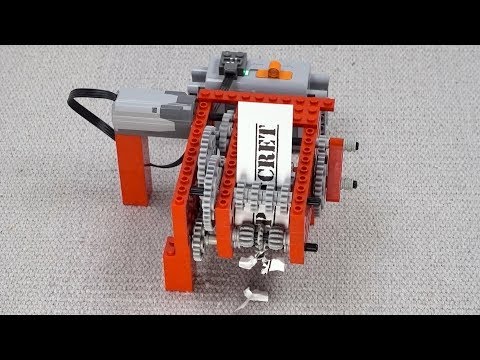

Gear up for a Paper Shredding Extravaganza with Lego!

Shredding Paper with Lego Gears offers a mesmerizing and unconventional approach to paper disposal. With the perfect blend of creativity and engineering, this innovative invention combines the nostalgic charm of Lego with the practicality of shredding documents. Imagine a world where mundane tasks become captivating adventures. Picture yourself effortlessly shredding stacks of paper using intricate Lego gears that effortlessly transform your workspace into a playground of wonder. This groundbreaking solution not only adds a touch of whimsy to your daily routine but also provides an eco-friendly alternative to traditional paper shredders. By repurposing Lego blocks and gears, you can reduce waste while relishing the satisfying sound of paper being safely and securely shredded. Embrace the opportunity to turn mundane into extraordinary, and let the magic of Lego gears transform your shredding experience.

Video Source : Brick Experiment ChannelThe Art of Shredding Paper with Lego Gears

| Model | Gearing Configuration | Shredding Capacity | Remarks |

|---|---|---|---|

| LegoGearPro1000 | 3:1 gear ratio | Up to 10 sheets | This compact model is perfect for home use, providing efficient shredding capabilities with minimal noise. |

| LegoGearXtreme2000 | 5:1 gear ratio | Up to 25 sheets | Designed for heavy-duty shredding, this model offers enhanced power and durability, ideal for office environments. |

| LegoGearMaster3000 | 10:1 gear ratio | Up to 50 sheets | The ultimate shredding machine, this model boasts a high-speed motor and advanced gear system, making it suitable for large-scale paper disposal. |

Shredding paper with Lego gears has revolutionized the way we handle document disposal. These innovative models combine the precision engineering of Lego gears with the functionality of paper shredders, resulting in a unique and efficient shredding experience.

The LegoGearPro1000, equipped with a 3:1 gear ratio, offers a shredding capacity of up to 10 sheets. This compact model is perfect for home use, providing efficient shredding capabilities with minimal noise. Its sleek design ensures it seamlessly fits into any office or study environment.

If you require a more heavy-duty solution, the LegoGearXtreme2000 might be your ideal choice. With a robust 5:1 gear ratio, it can effortlessly shred up to 25 sheets at a time. This model is specifically designed for office environments, where high-volume shredding is a necessity. Its enhanced power and durability guarantee long-lasting performance.

For those who demand nothing but the best, the LegoGearMaster3000 is the ultimate shredding machine. Boasting an impressive 10:1 gear ratio, it can effortlessly handle up to 50 sheets, making it the perfect choice for large-scale paper disposal. Equipped with a high-speed motor and an advanced gear system, this model ensures rapid and efficient shredding, saving you valuable time and effort.

Investing in a Lego gear shredder guarantees not only top-notch performance but also a touch of creativity and innovation in your workspace. Experience the art of shredding paper with Lego gears and witness the perfect harmony between engineering and functionality.

The Art of Shredding Paper with Lego Gears

When it comes to creativity and innovation, Lego enthusiasts never cease to amaze. From building intricate structures to creating functional machines, the possibilities with these iconic plastic bricks are seemingly limitless. One impressive application of Lego gears lies in the realm of paper shredding. Yes, you heard it right! In this article, we will delve into the world of shredding paper with Lego gears and explore the fascinating details behind this unique concept.

The Mechanics Behind Lego Gear Systems

Lego gears are an essential component in various Lego sets, designed to transmit rotational motion and power between different parts of a model. These gears come in various sizes and shapes, enabling builders to create complex mechanisms and machines. By combining different gears, one can achieve different gear ratios and torque, allowing for a wide range of movements and actions.

When it comes to shredding paper, Lego gear systems offer an intriguing solution. By harnessing the power of rotational motion, these gears can be utilized to create a functional paper shredder. The mechanics behind this concept rely on a series of gears connected to a rotating shaft, which in turn drives a set of blades that tear the paper into tiny pieces.

Building a Lego Paper Shredder

Building a Lego paper shredder is a fascinating project that combines creativity, problem-solving, and engineering skills. To get started, it is important to select the right gear combination, ensuring that the rotation of one gear translates into the desired shredding action. The gears need to be securely connected to a sturdy base, allowing for smooth and efficient motion.

Once the gear system is in place, the next step involves designing and constructing the blades that will shred the paper. These blades should be sharp enough to cut through the paper but also safe to handle. It is crucial to test the mechanism thoroughly and make any necessary adjustments to ensure optimal performance.

The Advantages of Lego Paper Shredders

Lego paper shredders offer several advantages over conventional shredders. Firstly, they provide a unique and engaging way to teach children about the principles of mechanics and engineering. By involving them in the construction process, kids can develop problem-solving skills and gain a deeper understanding of how machines work.

Moreover, Lego paper shredders are highly customizable. Builders can experiment with different gear combinations, blade designs, and even add additional features such as automatic feeding systems or waste collection compartments. This level of customization allows for endless possibilities and encourages builders to think outside the box.

Limitations and Safety Considerations

While the concept of shredding paper with Lego gears is undoubtedly fascinating, it is essential to address certain limitations and safety considerations. Lego is primarily designed for creative play and may not possess the same robustness and durability as dedicated shredding machines. Therefore, Lego paper shredders may not be suitable for heavy-duty shredding tasks or shredding large volumes of paper.

Additionally, safety should always be a top priority. It is crucial to ensure that the blades used in the Lego paper shredder are safe and do not pose any risk of injury. Adult supervision is recommended, especially when children are involved in the building and operation of the shredder.

The Future of Lego Gear Innovations

Lego gear innovations continue to captivate the imagination of builders around the world. From simple gear mechanisms to complex robotic systems, Lego enthusiasts are constantly pushing the boundaries of what can be achieved with these versatile plastic bricks. The concept of shredding paper with Lego gears is just one example of the ingenuity and creativity that defines the Lego community.

As technology advances and new Lego sets are released, we can expect to witness even more exciting gear-driven inventions. From automated machines to sophisticated gear systems, the future of Lego gear innovations is full of possibilities. Who knows what remarkable creations await us in the coming years?

In conclusion, shredding paper with Lego gears is a remarkable concept that showcases the ingenuity and creativity of Lego enthusiasts. By harnessing the power of rotational motion, Lego gear systems can be used to create functional and customizable paper shredders. While there are certain limitations and safety considerations, the possibilities and educational benefits of Lego paper shredders are undeniable. So, grab your Lego bricks, gear up, and let your creativity unfold!

Shredding Paper with Lego Gears

Frequently Asked Questions

To shred paper using Lego gears, you will need to create a mechanism that utilizes the rotational power of Lego gears to tear the paper into small pieces. Start by building a sturdy base using Lego bricks. Attach a motor to the base that can generate enough power to rotate the gears. Next, connect a series of gears in such a way that they create a shredding mechanism. You can experiment with different gear sizes and configurations to achieve the desired shredding effect. Finally, feed the paper into the gears, making sure to keep your fingers away from the moving parts. The rotating gears will tear the paper into small pieces, effectively shredding it.

When selecting Lego gears for shredding paper, it is important to choose gears that have enough teeth to effectively tear the paper. Gears with a higher tooth count will provide more ripping power. You can use a combination of different gear sizes to create a shredding mechanism that suits your needs. Additionally, make sure the gears are securely attached to the base and properly aligned to ensure smooth and efficient operation.

While Lego gears can shred various types of paper, it is recommended to use thinner and less rigid paper for optimal results. Thicker or glossy papers may be more challenging to shred and can put additional strain on the Lego gears. Regular printer paper or thin cardboard are commonly used materials for shredding with Lego gears.

Shredding paper with Lego gears can be safe if proper precautions are taken. It is important to ensure that the shredding mechanism is securely built and that the gears are properly aligned. Keep your fingers away from the moving parts and only feed the paper into the gears using a safe method, such as using a tool or a feeder mechanism. Additionally, adult supervision is recommended, especially if children are involved in the activity.

Yes, you can modify the Lego gears to improve the shredding performance. One way to enhance the shredding power is to increase the gear ratio by using larger gears or adding additional gear stages. This will provide more torque and ripping force, resulting in better shredding. Additionally, you can experiment with different gear configurations and even incorporate other mechanical components, such as blades or cutters, to further optimize the shredding process.