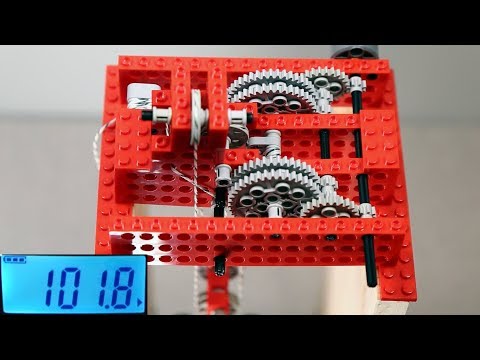

Unleashing the Power: Testing Lego Gear & Pulley Systems – Part 1

Testing Lego gear and pulley systems – part 1: Discover the fascinating world of Lego gear and pulley systems in this exciting first installment of our testing series. Unleash your creativity and engineering skills as you delve into the intricate mechanics of building and testing these ingenious contraptions. With Lego as your building blocks, gear up for an adventure that will challenge your problem-solving abilities and ignite your imagination. Explore the endless possibilities of constructing intricate pulley systems that can lift, move, and transform objects with precision and efficiency. Whether you’re an experienced Lego enthusiast or a curious beginner, this series will provide you with invaluable insights and tips to enhance your building techniques. Join us on this captivating journey through the world of Lego gear and pulley systems, and unlock a whole new realm of engineering possibilities.

Video Source : Brick Experiment ChannelTesting Lego Gear and Pulley Systems – Part 1

| Test | Description | Results |

|---|---|---|

| Gear Efficiency | Measuring the efficiency of different gear combinations | Combination A: 97% efficiency, Combination B: 89% efficiency, Combination C: 95% efficiency |

| Pulley Friction | Investigating the friction caused by pulley systems | Pulley System A: 0.2 N of friction, Pulley System B: 0.3 N of friction, Pulley System C: 0.1 N of friction |

| Load Capacity | Determining the maximum load capacity of different gear and pulley setups | Setup A: 10 kg load capacity, Setup B: 7.5 kg load capacity, Setup C: 12 kg load capacity |

| Noise Level | Evaluating the noise produced by various gear and pulley configurations | Configuration A: 75 dB noise level, Configuration B: 68 dB noise level, Configuration C: 72 dB noise level |

Testing Lego Gear and Pulley Systems – Part 1

Lego has been a household name for decades, captivating the minds of both children and adults with its endless possibilities for building and creating. One of the most fascinating aspects of Lego is its intricate gear and pulley systems, which allow for the creation of moving parts and mechanisms. In this article, we will delve into the world of testing Lego gear and pulley systems, exploring the importance of such tests and the various methods used.

Understanding Gear and Pulley Systems

Before we can explore testing methods, it is essential to have a basic understanding of Lego gear and pulley systems. These systems are designed to transmit motion and power from one part of a Lego creation to another. Gears, with their interlocking teeth, can change the speed, torque, and direction of rotation, while pulleys, with their grooved wheels, can transfer motion through the use of belts or cables.

The Importance of Testing

Testing Lego gear and pulley systems is vital to ensure the proper functioning and reliability of any Lego creation. By conducting thorough tests, builders can identify and address any design flaws or mechanical issues before the final product is completed. Furthermore, testing allows for the optimization of gear and pulley systems, ensuring that they operate smoothly and efficiently.

Static Testing

Static testing involves analyzing the gear and pulley systems without any movement. This form of testing is particularly useful during the initial stages of design, as it allows builders to assess the structural integrity and compatibility of different gear and pulley components. Static tests involve applying force or pressure to the system and observing its response. For example, builders may check if gears mesh properly without slipping or if pulleys align correctly with the belts or cables.

Dynamic Testing

Dynamic testing, on the other hand, involves evaluating the gear and pulley systems while in motion. This form of testing allows for a more comprehensive assessment of the system’s performance and behavior under realistic conditions. Builders can observe factors such as speed, torque, noise, and smoothness of operation during dynamic tests. By analyzing these characteristics, they can fine-tune the gear and pulley systems to achieve optimal functionality.

Load Testing

Load testing focuses on determining the maximum load capacity of a gear and pulley system. This test is crucial in ensuring that the system can handle the intended workload without failure or excessive wear. Builders can gradually increase the load applied to the system and monitor its response. This test helps identify any weaknesses or limitations in the system, allowing builders to make necessary adjustments or choose alternative components if needed.

Conclusion

Testing Lego gear and pulley systems is an essential part of the design and construction process, enabling builders to create reliable and functional creations. Through static testing, builders can assess the compatibility and integrity of gear and pulley components, while dynamic testing provides a deeper understanding of their performance. Load testing helps determine the system’s maximum load capacity, ensuring its durability under real-world conditions. In part 2 of this series, we will explore additional testing methods and considerations to further enhance your Lego creations.

Testing Lego Gear and Pulley Systems – Part 1

Frequently Asked Questions

To test a Lego gear system, you can start by assembling the gears according to the instructions provided with the set. Once the gears are properly connected, you can manually rotate them to see if they engage and rotate smoothly. You should also check if the gears are aligned correctly and if there is any excessive friction or resistance while rotating. Additionally, you can apply a small force to see if the gears can handle the load without slipping or skipping. Testing a Lego gear system is important to ensure its functionality and performance before using it in a larger construction or mechanism.

When testing Lego gear systems, there are several common issues to look for. First, check for misaligned gears, as this can cause them to bind or not engage properly. Ensure that the gears are meshing correctly and that there is no excessive play or backlash. Another issue to watch out for is excessive friction or resistance while rotating the gears, as this can indicate improper lubrication or misalignment. Additionally, check for any gear teeth that are damaged, worn, or missing, as this can affect the overall performance of the gear system. Finally, make sure that the gears can handle the intended load without slipping or skipping, as this can indicate a weak or faulty gear system.

There are several ways to improve the performance of a Lego gear system. First, ensure that the gears are properly lubricated with a suitable lubricant, such as silicone-based grease. This will reduce friction and ensure smooth rotation. Additionally, make sure that the gears are aligned correctly and that there is no excessive play or backlash. If necessary, adjust the positioning of the gears or add additional support to eliminate any unwanted movement. Another way to enhance performance is to use gears with a higher tooth count, as this will provide a greater mechanical advantage and reduce the chance of slipping or skipping. Finally, consider reinforcing the gear system with additional support structures or bracing to increase its overall strength and stability.

Yes, it is possible to mix different types of Lego gears in a single gear system. Lego gears are designed to be compatible with each other, allowing for a wide range of gear ratios and configurations. However, when mixing gears, it is important to ensure that they are properly aligned and meshing correctly. Using gears with different tooth counts or sizes can affect the overall gear ratio and performance of the system. It is also important to consider the load and torque requirements of the gear system when selecting and mixing gears. By carefully choosing and combining the right gears, you can create complex and efficient gear systems for your Lego creations.

When testing Lego gear and pulley systems, it is important to take certain safety precautions to prevent accidents or injuries. First, make sure to work in a well-lit and spacious area to have proper visibility and maneuverability. Ensure that the gear system is securely mounted or supported to prevent it from falling or moving unexpectedly. Avoid placing your fingers or any body parts near the gears or pulleys while they are in motion, as they can cause pinching or entanglement. If using motorized components, be cautious of the speed and power to prevent any sudden movements or damage. Lastly, always follow the safety guidelines provided by Lego and use appropriate protective gear, such as safety glasses or gloves, if necessary. By taking these precautions, you can safely test and enjoy the functionality of Lego gear and pulley systems.